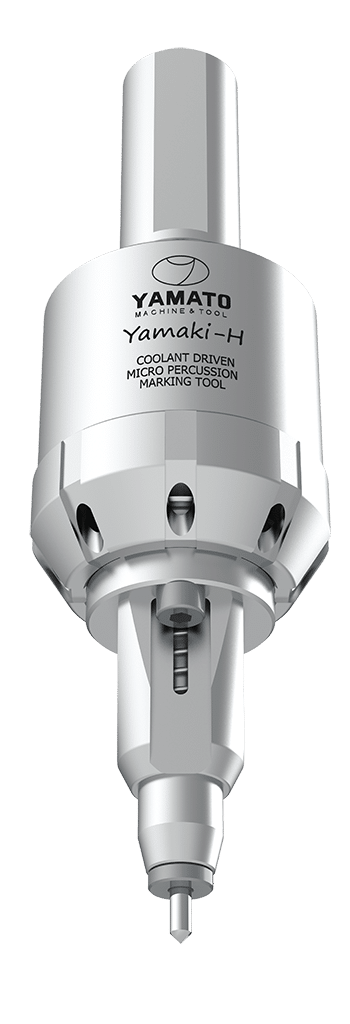

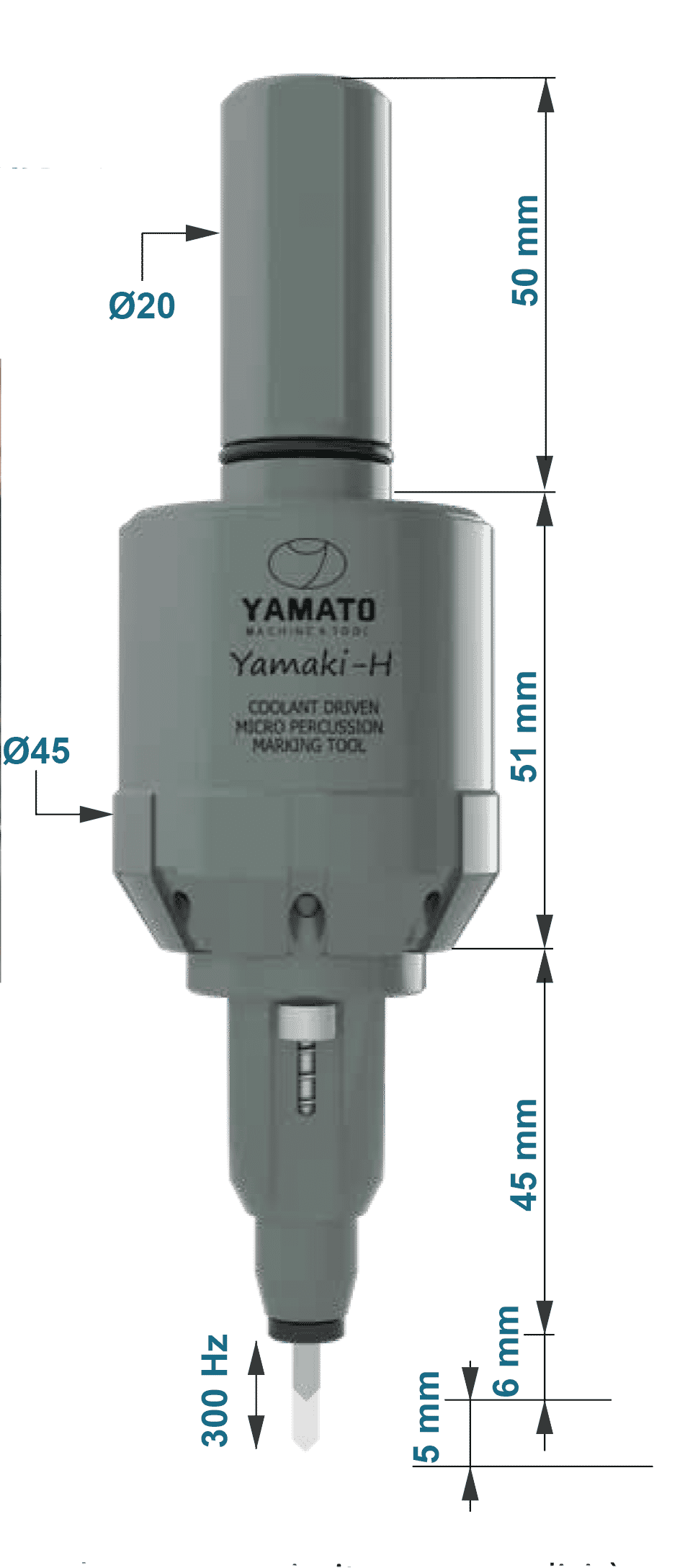

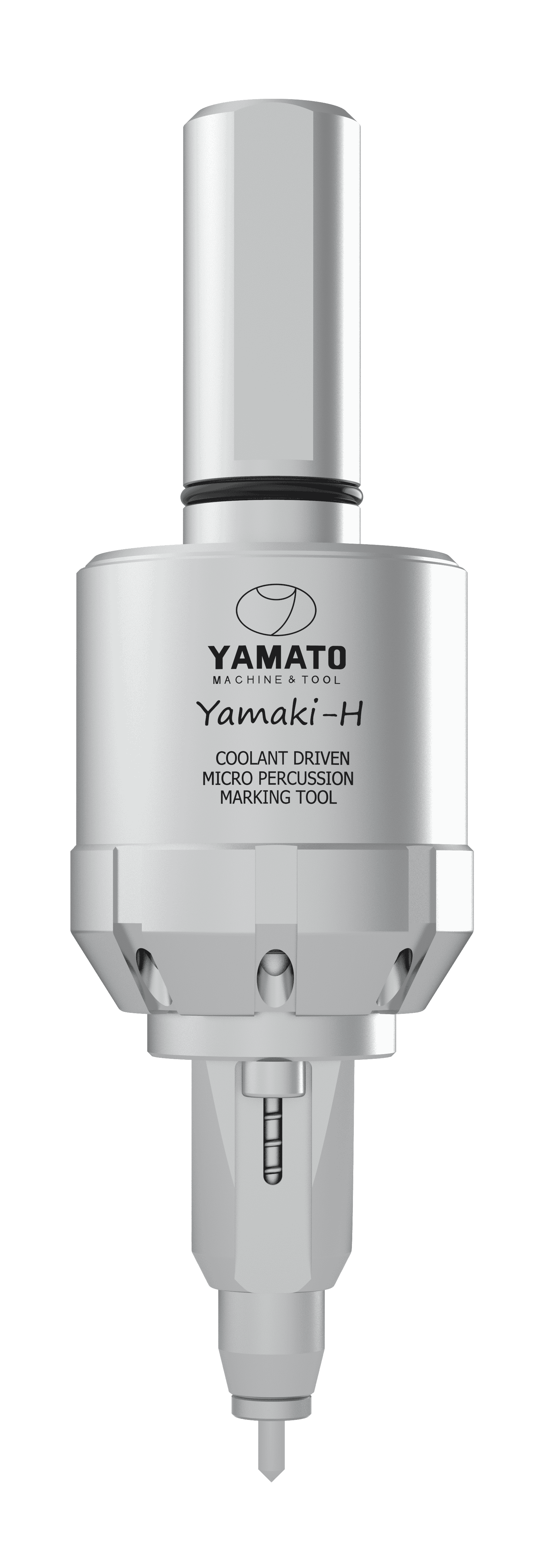

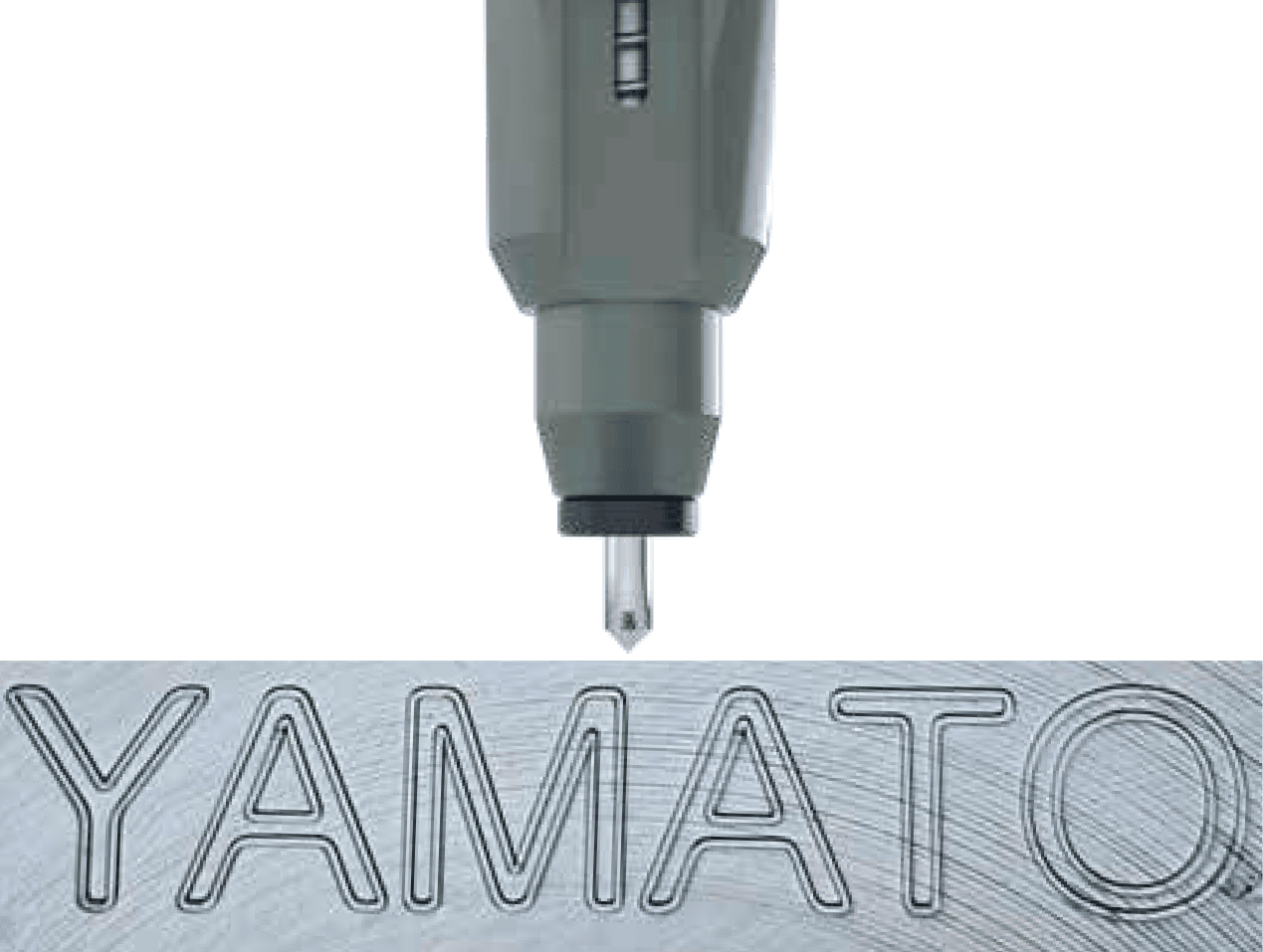

Yamaki-H Coolant Driven – Micro Percussion

Coolant Driven Needle

-

The hydraulic marking tool works on the principle of dot peening.

-

The carbide needle starts to oscillate as soon as the coolant system is activated.

- It makes deeper markings than pneumatic marking tools, because

high power-pressurized coolant is used. - Thanks to the high frequency of strokes generated by the turbine system inside the tool, the marked text/shape appears as a contunious line.

-

All stainless steel body and components.

-

Tool can be used on machining centres, CNC lathes, etc. (no additional installations required)

-

The spindle of the machine does not need to be rotated.

MARKING TOOLS

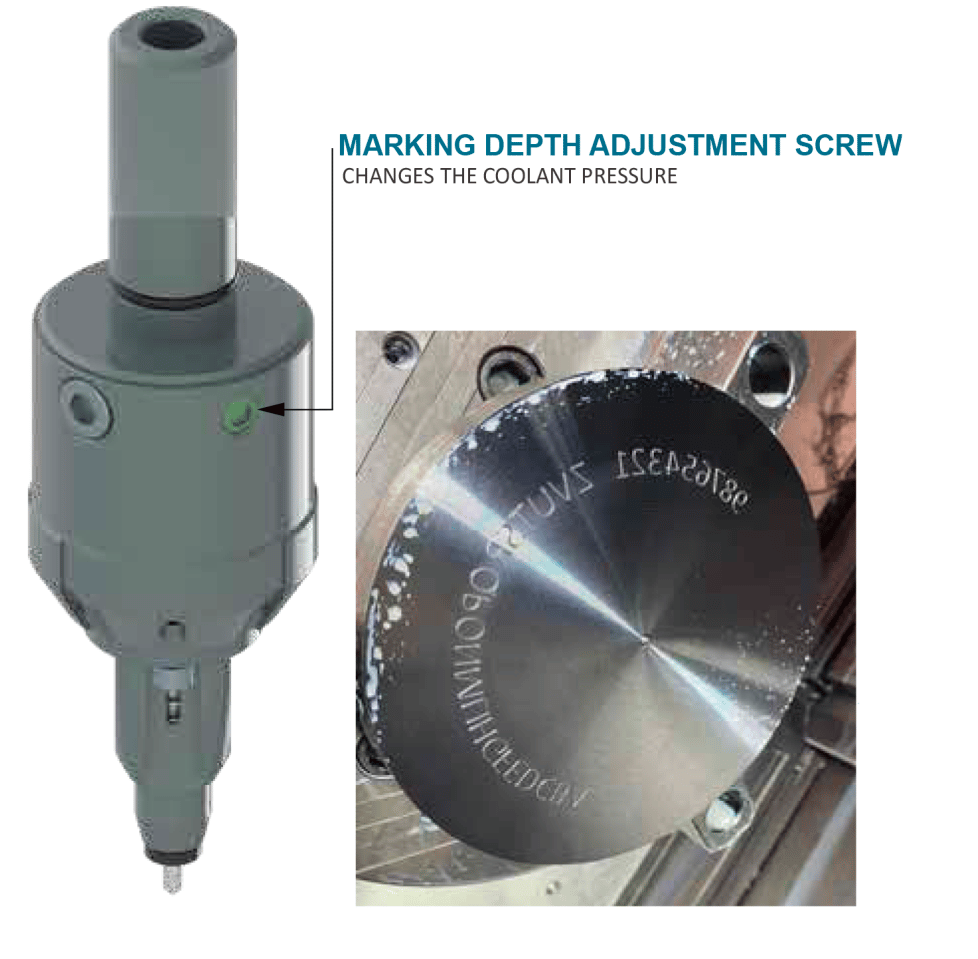

- The marking needle oscillates with min. coolant pressure of 10 bar supplied from the internal cooling system of the machine. Max. working pressure is 50 bar.

- Marking depth can be adjusted easily by the pressure adjustment screw on the tool.

- Needle has 5 mm axial compensation capability. Irregular (or curved) surfaces can be marked at the same depth.

- The carbide marking needle is almost wear-free. It can be replaced by the user.

- Marking can be done on all materials up to 62 HRC.

- Feeds more than 5.000 mm/min are possible.

YAMAKI-H

COOLANT DRIVEN – MICRO PERCUSSION